Hydraulics for waste compactors

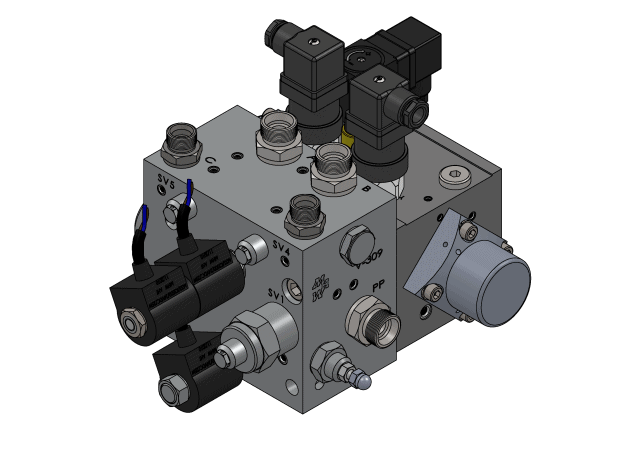

Main Hydraulic Manifold Block for Waste Compactors

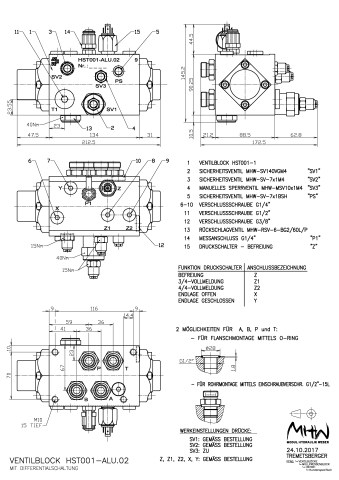

The self-switching 4/2-way valve block NG16 is suitable for mobile and stationary systems and is known for its compact design and is exclusively hydraulically controlled. Without electricity, cables and solenoid valves, it is moisture-insensitive and is perfectly suited for outdoor operation and in damp rooms. The valve block, like most of our hydraulic manifold blocks, is specially coated and corrosion-free.

The hydraulic manifold block provides full function, even with leaking cylinders, up to an internal leakage of 6L/min! This is ensured by the cylinder synchronization valve.

The main slide is absolutely wear-free due to the special ceramic coating.

The standard integrated end position damping ensures low-noise switching behavior at both switching points. The newly developed soft switching valve completely eliminates the undesirable and disturbingly loud noise when the end switching point is reached. An integrated pressure switch, used for the emergency “release” function, guarantees perfect operation even at lowest temperatures.

This is achieved with a weight of the operational valve block of only 4kg, which is less than half of other products on the market.

The main manifold block is absolutely wear- and maintenance-free. The possible option of the specially designed pressure filter fitting, eliminates the potential downtime due to contaminated oil. Clean, filtered hydraulic oil is a basic requirement for the smooth operation of all valves. The main sources of contaminated oil are slag residues from welds abrasion generated from pumps and cylinders.

Depending on customer preference the manifold block can be equipped with or without an integrated differential circuit. Optionally, our pressure switches are also integrated for the 3/4 – and 4/4-signaling and the end position.

The position of the cylinders can be monitored by means of integrated sensors. The signal only needs to be connected to the existing PLC and gives maximum control and the greatest possible insight into the compactor press.

The connection options in any mounting position include a plate assembly by means of an O-ring or a line connection with screw-in fittings.

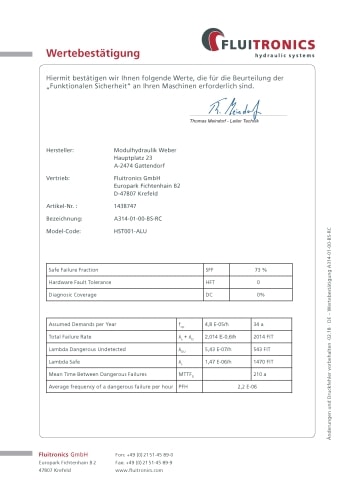

Main Hydraulic Manifold Block

Downloads

Accessories

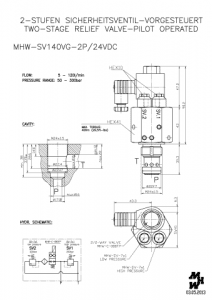

2-stage safety valve MHW-SV-140VG-2P

This valve is used in conjunction with an additional block for forced switching during grille lifting. The two pressure ranges are individually adjustable. When the solenoid valve is energised, the low pressure is deactivated so that only the higher set pressure is effective.

- interchangeable with safety valve MHW-SV140VG

- easy adjustment or readjustment of the two pressure ranges

- robust and simple construction

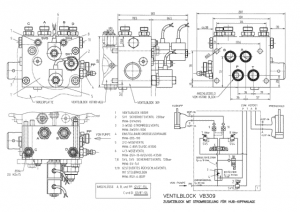

Additional control block for tilt and lift units

VB 309

This control block is used to control a lift-tilt system. Its main task is to reduce the pump flow for the volume-flow-controlled supply of the lift-tilt system. It contains all the necessary valves for controlling the lift-tilt system.

- Directly flange-mounted to the main control block

- no additional pipe fittings or hoses necessary

- Compact and clearly arranged unit

- throttle-free oil volume distribution

- Low operating noise

- safety valves for adjusting the lifting and lowering pressure

Pressure filter

DFP-40L-G1/2

These pressure filters prevent dirt or other impurities in the hydraulic oil from entering the main control block. They are fitted to ports A, B (cylinder) and P (pump). Can be used for both flow directions.

- max. 300bar

- max. 40L/min

- 200µ

Get in touch!

Contact

Modulhydraulik Weber GmbH

Hauptplatz 23

2474 Gattendorf

+43 (0) 2142/6426 0

+43 (0) 2142/6434