Hydraulic Cylinders

All Aluminum Cylinders – “Lightweights” for Extreme Conditions

The weight of our all-Aluminum cylinders, made of high-strength Aluminum alloys, is one-third of the weight of steel cylinders.

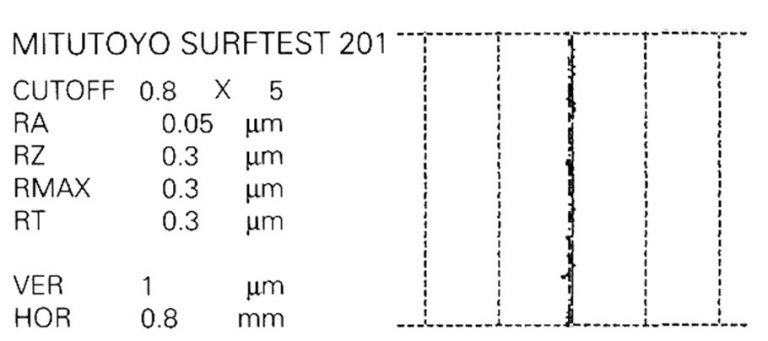

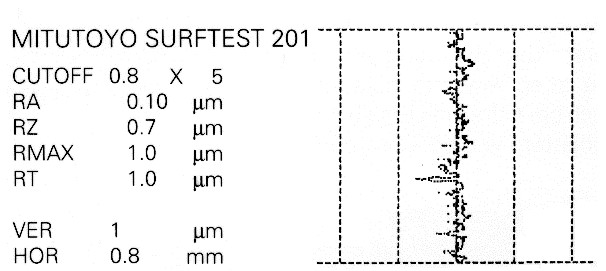

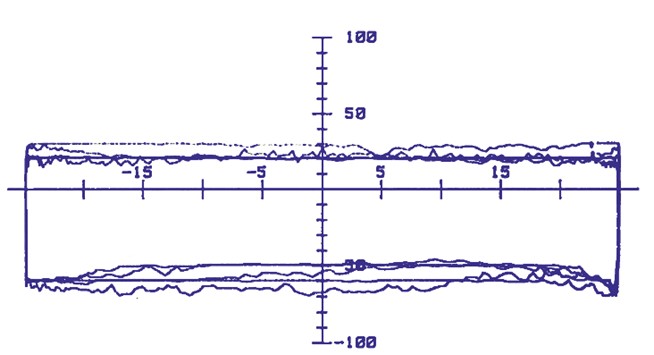

The cylinder tubes and pistons are manufactured out of one piece and are electrically non-conductive – therefore is virtually no corrosion possible. The extremely smooth ceramic surface allows dry operation. With an average material roughness of RA 0,05µ, the special surface is five times smoother than hard chrome. The surface hardness is 925 HV +/- 15 HV.

The cylinders are seawater resistant – which means absolutely no corrosion or wear in that harsh environment even after years of exposure.

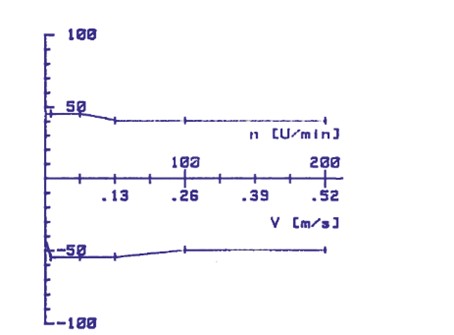

There are neither hairline cracks nor does the material peel off, as it is a homogeneous molecular structure throughout. The seals and guide rings operate silently at all temperatures and require no maintenance – even after years of use! This is guaranteed by the Teflon sealing system, which operates precisely without any “stick-slip” effect.

A selection of our hydraulic cylinders

Further information

Independent tests by the “Nippon Weathering Center” in Japan have rated the indestructibility of the surface with “excellent” results and have certified a service life of 20 years, without seal replacement.

In salt spray tests according to DIN EN ISO 9227, no corrosion was detectable after 648 hours. In comparison, hard chrome shows signs of corrosion on the base material already after 40 hours of salt spray testing.

Areas of application of the all-Aluminum cylinders:

- Liftgates and hoists

- Aerial work platforms

- Hydraulics for ambulance vehicles and beds

- Hydraulics in maritime applications

- Heavy-duty applications

- Food industry

- Off-shore

- Applications where there is a risk of corrosion

- Machine tools

Our all-Aluminum cylinders work with a wide variety of operating fluids: synthetic oils, biodegradable hydraulic oils, aggressive fluids, clear water, and salt water.

The cylinders are delivered ready for installation.

We comply with every customer specification such as working pressure, installation dimensions, stroke, etc. and are not satisfied until all customer demands are met.

Have a look at our brochure! If our products sparked your interest, do not hesitate to contact us!

Get in touch!

Contact

Modulhydraulik Weber GmbH

Hauptplatz 23

2474 Gattendorf

+43 (0) 2142/6426 0

+43 (0) 2142/6434